CONSULTING

We offer our experience and competencies in the field of process automation to end-user companies as a consultancy service.

The accuracy of the choices made in the early stages of the projects creates very important value for our customers over the years. We provide the necessary expertise from a single source to identify business needs and manage automation projects in the most effective way.

ENGINEERING

The success of Industrial Projects depends on the quality of an engineering process that has been handled with all its details.

As a company structured in line with the needs of EPC companies, we can provide the entire set of documents that an automation project needs from a single source. Preliminary design (FEED), basic and detailed engineering, and documentation phases are handled with great care, thus helping to make significant savings throughout the project.

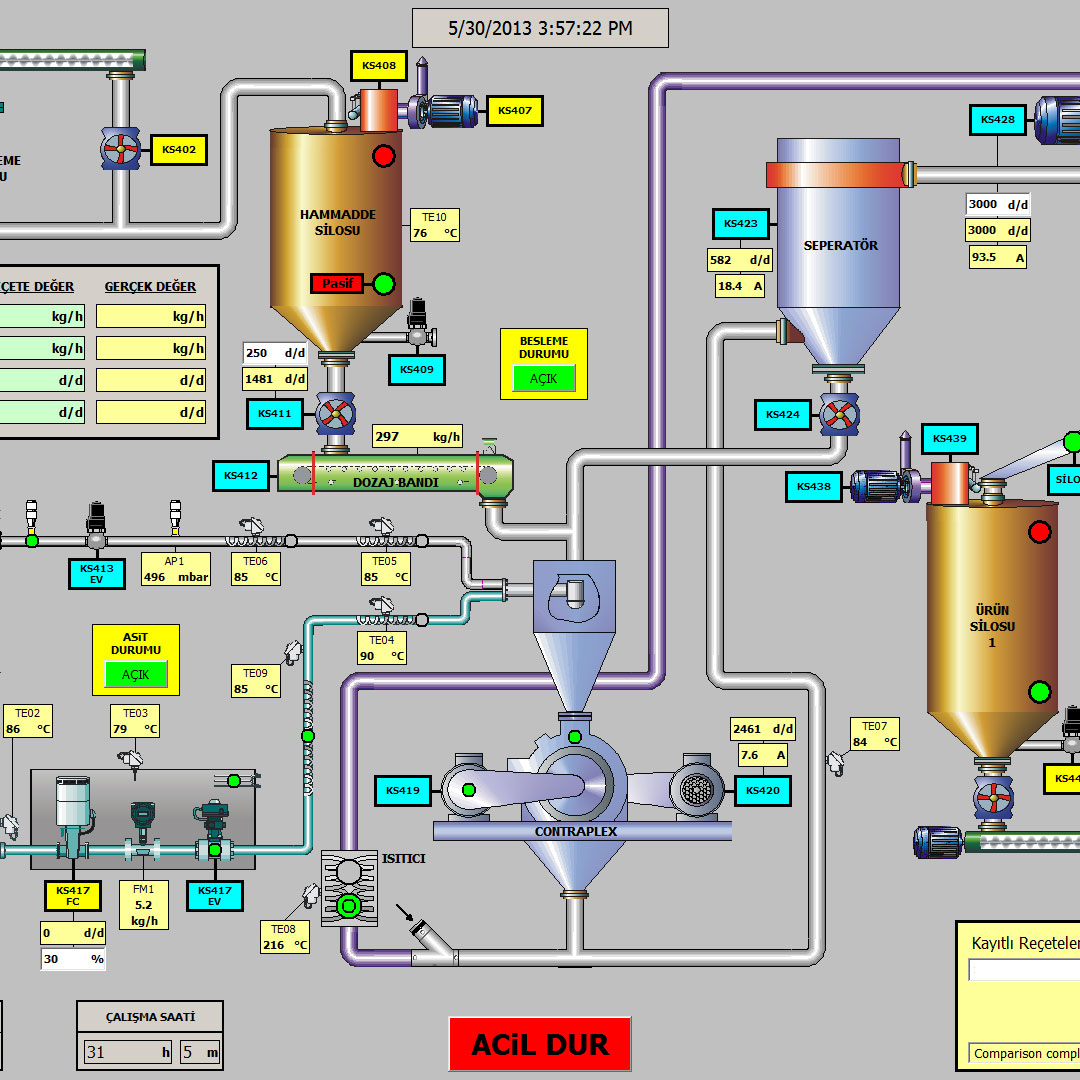

APPLICATION - SYSTEM INTEGRATION

We bring a whole new dimension to system integration with our application experience of more than twenty years in industrial process automation. With our integrated engineering management process, we help complete and harmonious completion of all links of the chain, and successfully conclude the most complex application studies with a comprehensive test and FAT process.

INDUSTRIAL DATA MANAGEMENT

Industry 4.0, IIoT and the Cloud offer businesses the opportunity to be part of a cultural revolution.

Increasing global competition requires the elimination of all factors that lead to loss of efficiency in production environments. For this purpose, companies need to establish a reliable and fast data collection system in the first place, and then create an environment to evaluate this data.

For nearly ten years, we have been providing data-based production systems services to enterprises, thus providing competitive advantage at every stage of production.